Working Principle:

* This heavy duty dispenser, equipped with stable electricalcomponents and accurate flow meter, ensure good performance, accuracy, and easy to be operated and maintained.

* This heavy duty dispenser is driven by a separate pumping unit nearby. The pumping unit should be equipped with 5KW~7.5KW motor, to ensure flow rate at 25-35m³/hour and pumping lift is around 32 meters of water.

* Specially designed Explosion-proof Separating Cabinet, with150mm height, which divides the whole unit into two parts, the upper part is electronic unit, including main board, display and keypad box, etc. Under the Separating Cabinet, there is explosion proof area, including explosion-proof solenoid valve, flow meter, explosion-proof junction box, and explosion-proof communication box, explosion-proof pulser.The two parts are wellsealed and isolated.

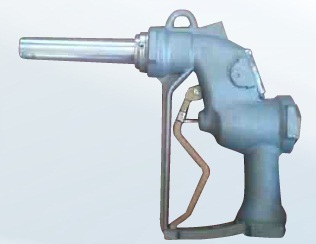

1.Hose Reel 2. DN40 Self-sealing Nozzle

Advantages:

1. Two flow meter, high flow rate meter and spare turbine meter as alternative one used in emergency.

2. Crane rotating pipe (option) and hose used for flexible refueling at different position and direction.

3. Specially designed nozzle holder made of steelpipe, for dropping liquid collection.

4. Rotating nozzle for convenient operation

5. Automatic heating device for the pipe system..

6. Dualflow rate controlsolenoid valve for accurate measuring.

7. Good accuracy, heavy duty, low noise.

8. Data safe , backup power able to keep the display on at least 15 minutes. Fueling data can be saved for long time

9. Matured computer controltechnology, easy and safe operation.

10. Automatic check function, reset to 0 automatically every time.

11. Preset function, preset volume or amount , preset by backstage system.

12. Stable and good performance. Separate Strong power and weak power system.

13. large lCD display, with back lighting for night viewing